Fueling stations present unique problems that will damage and prematurely erode trench drain systems if not properly designed and installed. Dura Trench linear drainage systems are created to withstand the harsh environmental elements of fueling stations. Dura Trench channels are proven to be resistant to gasoline, motor oils, road salts, & anti-freeze.

This Fueling station video by Dura Trench is best viewed with audio. Click above to turn the audio on.

Design Considerations

Sizing the drain

- The design capacity of the trench is determined by the amount of runoff that will be captured by the drain. The most common method for determining this is the Rational Method (Q=CIA where Q is the design flow)

- In sheet flow applications, you may need to size the drain up to catch the water in applications where there is a steep slope. Otherwise, the size of the drain should heel the hydraulic requirements of the channel.

- Designers tend to oversize trench drains to be conservative or over-plan for very large storms. Avoid doing this as the low flow rates allow for the build-up of debris and cost you extra money. A radius bottom trench drain may help but it is wise to design near actual capacity when possible.

- Be sure that the outlet capacity does not limit the flow of the drain. Outlet connections can be piped to structures or the trench can run directly into a structure. If piping to a structure, make sure the pipe is sufficiently large (usually 8″ or 12″ is sufficient). If you are going directly into the structure, be careful not to limit flow into the structure. The frame or lid of a precast structure can be very thick and the entire channel cross-section should be turned under the frame or lid to ensure maximum flow capacity.

Choosing the Channel

- Exterior applications are subject to thermal cycles and/or freeze-thaw cycles, ultraviolet light, cyclic loading, and often heavy traffic. The channel material should be composed of a material that expands and contracts at a similar rate as the surrounding concrete. The channel material should not be affected by UV light. The channel material should not be between the frame of the system and the concrete unless the compressive strength of the material is at least as strong as the surrounding concrete. The material should be of sufficient thickness and strength to handle the constant cyclic loading that vehicle traffic subjects the system to. For this type of application, there are several systems available.

- It is best to use a frame with a substantial thickness (typically steel) to distribute the loads and protect the trench integrity. Some gas station applications can use a system that has a lighter duty frame if the traffic is at slow speeds and the vehicles will not be turning on the drain. One of the most common failure modes observed is improper anchors on the frames and lack of bearing area under the frames. Remember, the frame will take the entire load that the grate is subjected to and transfer that to the concrete under it. If there is not sufficient concrete under that frame, the concrete can sheer off and cause the system to fail. Learn more about loading and material properties of grates and channels.

- In exterior applications, you need to ensure that the drain will not degrade with exposure to ultraviolet light (UV light) and thermal expansion. This eliminates thermal set resin channels such as any HDPE materials. Another reason that you do not want to use a thermal set resin is that they are subject to ESC (Environmental Stress Cracking) which is a polymer failure that happens when foreign substances (such as oil and gasoline) impregnate the material and cause the long polymer chains to become disentangled and therefore lose any strength that they may have once had. This failure mechanism is especially prominent in gas stations where hydrocarbons are present.

- Use a radius bottom channel. The round bottom will help with the accumulation of debris by keeping the velocity of water high in the center of the drain where the debris is resting. The scouring velocity will help move this sediment through the system.

- Sealing channel joints is typically not necessary. Some areas will require the joints to be sealed due to freeze-thaw cycles but most states rely only on proper vibration of the concrete to prevent water from getting in the joints.

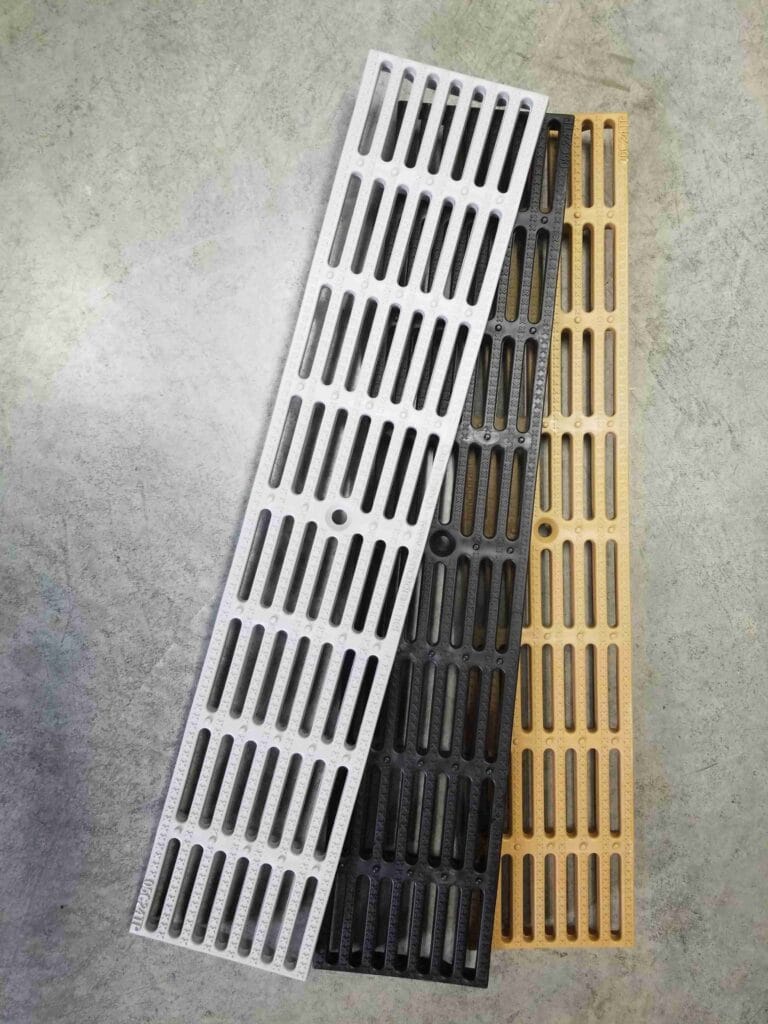

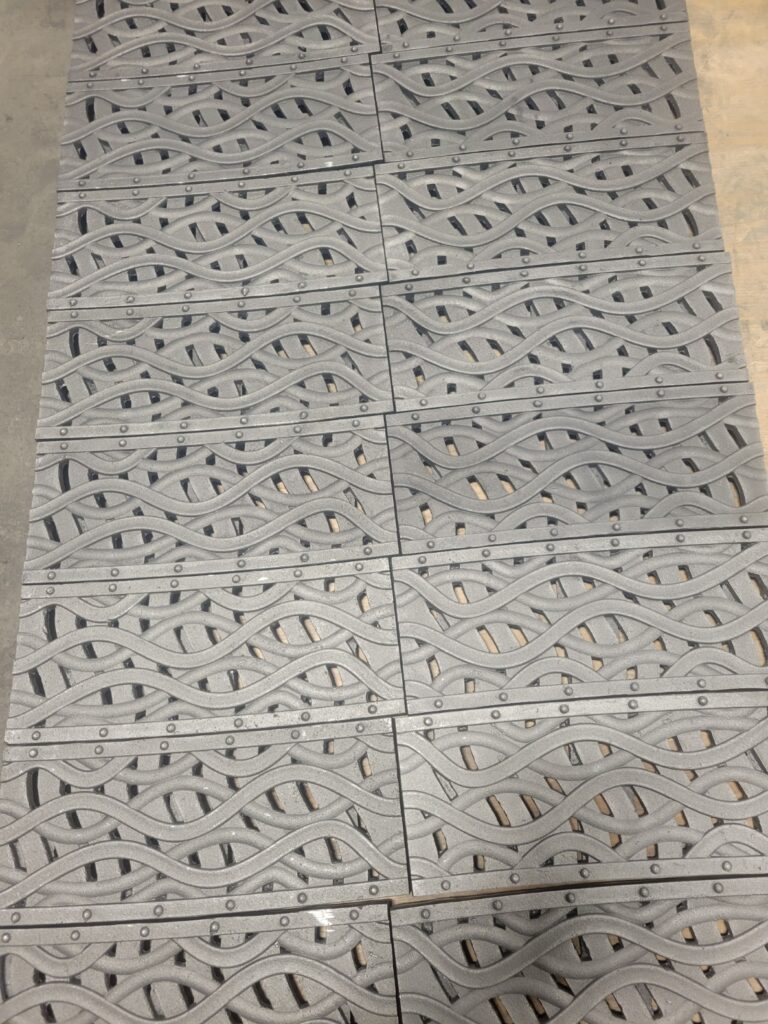

Selecting the Grate

- Grates for fueling station applications should be ductile iron. Cast iron grates are more susceptible to failure over time than ductile iron grates and cost little more than cast iron. Ductile iron is often chosen for its strength-to-weight ratio, especially in areas where removal of the grates may become necessary. Ductile iron grates typically have more open are because it takes less iron to get the required strength. This is critical with the amount of silt and debris that is present in a fueling station. The more open area and the larger the geometry of the openings the less likely the grate is to plug and not work properly. Conversely, in areas near the front of the store you may want to have grates with smaller openings due to the volume of pedestrian traffic and ADA compliance needs.

- Make sure that the openings on the grate are as large as possible to ensure that clogging is not a factor. The smaller the openings the more frequent cleaning of the grates will be necessary. The larger the openings the more likely the debris is to flush through the system.

- Be sure the grates are properly anchored so that they do not come out in the traffic that may be stopping, starting, or turning on top of the system.

Designing the Layout

- Trench drain runs along a pump island or in front of the store can be lengthy runs with flat longitudinal slope. Due to the long runs be aware of the depths of the trench drain systems. Use systems that can handle the long runs or choose to have multiple outlets.

- The depth of the system that you are going to use can conflict with piping and other buried utilities, especially around tanks and pump islands.

- Outlets should be placed to minimize piping, but try to avoid making the outlets further apart than necessary as the trench drain depth will increase. Increased trench drain depth increases the installed cost of the system.