The drainage that you use in your brewery is critical to your business operating safely and without issues due to health concerns. Preventing slips and falls, making sure that bacterial overgrowth does not cause people harm, and being certain that contaminants from the brewing process are properly disposed of are key. The drainage that you place in your brewery is essential to operating this kind of business safely and to the process of passing inspections every year.

There are businesses out there that use as much water and have as much water waste to attend to during normal operations as a brewery. The drainage that you are using in your working spaces, your loading bays, and even walkways needs to be correctly designed and properly installed to work optimally. You cannot have standing water or issues with spills impeding your work processes every day, and this is why you need to know which kinds of drainage you need for your brewery.

Knowing How to Choose the Right Drain for Your Brewery

The first thing that you should always consider when you are looking at drainage for a brewery is the max volume of water that might need to be attended to during any given day. This is not the base level of water that might be spilled or drained out during the brewing process. You need to know what the possible highest volume of water will be in any given area that could come into contact with spills, brewing drainage, or runoff.

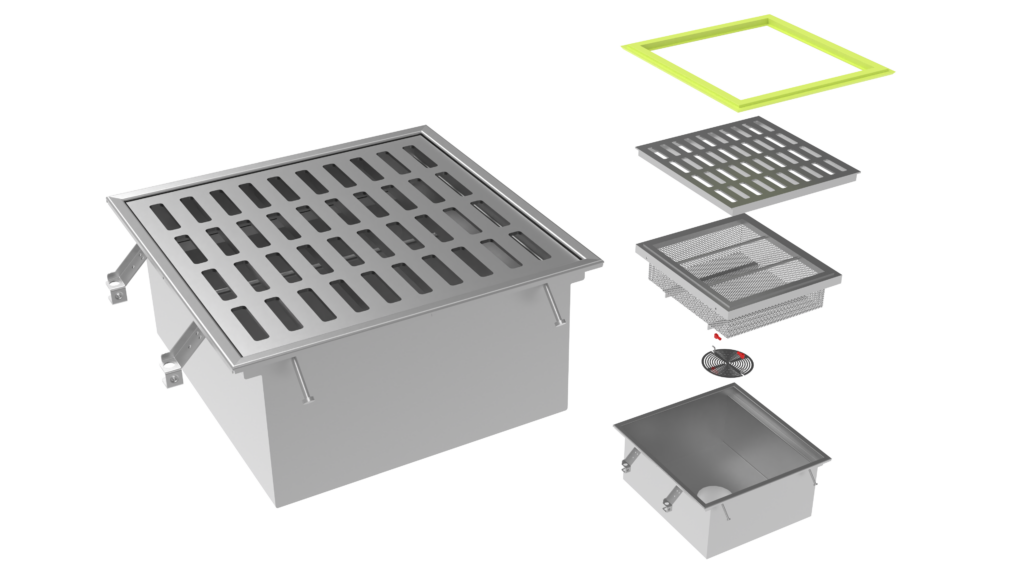

This information is essential so that you install the right size drain and the right style of gutter. Slot drains are very common in breweries because they are easy to keep clean, they do not pose a trip and fall hazard, and they are easy to reinforce. This is by far the most common kind of drainage that you will need in your brewery, but some other locations might also need central collection drains, or trench drains as well.

The slope and the style of the flooring can also impact the choice of which drain to use, and you should be aware that slot drains, while low-profile, might not be ideal in locations that do not have adequate slope built into the flooring already. Trench drains come with a slope built into the drainage system itself, which can help in areas that are not prepared to offer the right rate of drainage otherwise.

Always make sure that you work with a drainage installation expert if you are not sure about which kind of drains you might need in specific areas of your business. It is better to install the right drains from the start, and you will save money if you do not have to replace drains that have failed or that are not working right after they have been placed.

Considerations for Safety in a Brewery Trench Drain

When you are installing drainage for a workplace, you will need to be sure that your drains will not cause slips and falls, and other accidents. You do not want to have hurt employees due to incorrectly placed or covered drains, and you will also be exposing yourself to risks if you have vendors or other outside business partners onsite who get hurt.

Slot drains, and correctly covered trench drains are the safest drains to have in your brewery due to their low-profile nature and their ability to be made ADA-safe.

Materials For Your Brewery Drains

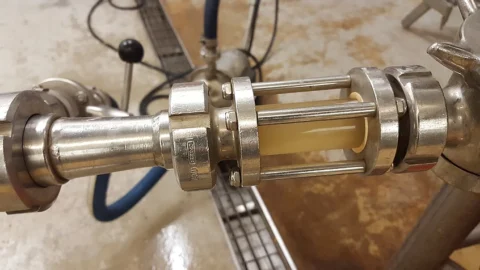

The other thing that you should be aware of when you are choosing drainage for your brewery is that you need to pick drains that are made of the right materials. The runoff water from brewery wastes is quite acidic, which can lead to the breakdown of some of the more common drainage materials. This might add some cost, but you do not want your drains to fail.

You will need to install stainless steel drains in many of the areas where brewing processes are completed because stainless steel will not be corroded or broken down by acidic liquids. The covers that you get for your drains can be made out of stainless as well, which means that these items will hold up to the challenge of daily exposure to a harsh pH.

Always make sure that you are certain that no acidic runoff will be present in areas where you place other kinds of drains. It can be easy to forget that acidic drainage will have to pass from a workspace through an area that is not used for brewing, causing damage to the drains in this section of the business. The demands of the use of brewery drainage are such that it is typically worth it to install stainless steel drains throughout your business.

Select Clog-Free Drains for Your Brewery

One of the hardest parts of keeping a drainage system healthy in a brewery is trouble with clogs in the drains. Many solids are part of the brewing process, and these can lead to clogged drains that overflow or break down over time. You will need to be sure that your drainage system is set up to handle tough solids that might break down lesser-quality drainage systems.

Slot drains are the least likely to get clogged, and they are the easiest drains to clean. Staff can easily sweep out and unclog these drains daily, which prevents issues with standing water, drainage system failure, and more. Cleaning out large clogs can also be quite costly, so you will want to be sure that you are not bleeding money every month for things like this which can be avoided.

Select Environmentally Friendly Drains for Your Brewery

Proper drainage in your brewery is also important in protecting the environment. Businesses that create potentially harmful chemicals and wastes are required to attend to the disposal of these wastes correctly. You can make sure that you are not causing toxic runoff to enter the sewer system and spread into the groundwater if you have the right drainage systems in place at your brewery business.

You will need to be sure that you are not going to impact the environment or end up paying fines or being shut down for environmentally unsafe processes and drainage systems in your business.

Choosing the Right Drain Is Important for Your Brewery

If you have a brewery, you need to be sure that every part of your brewery has the right drains in place for safety, to reduce health risks, and to make sure that you can attend to the wastewater from the brewing process properly. Keeping your brewery open for the operation depends on having safe drains in place throughout the brewery.

Make sure that you always reach out for advice about what kinds of drainage to place in your brewery if you are not sure. You will only lose time and money by having to replace incorrect drain selections, and you could open up your business to issues with environmental problems and accidents when you do not have the right drainage in place. Your brewery can operate without any issues related to drainage if you make sure that you have the proper drains in place that are made from the right materials.