Food safety is key for many reasons. Not only do these guidelines and regulations ensure that the food supply in the US is healthy and safe, but they also help to guide the workflows that you use every day at your factory or plant. Following the guidelines for food safety includes being sure that you have installed the proper drainage in all of the different areas of your plant or factory.

Food safety and food-safe drains are closely linked, and you cannot have one without the other. You might need to know more about the food safety features of food-safe drains so that you can be sure that your drainage installation is perfect.

What Are Food-Safe Drains?

Food-safe drains are made to ensure that food production areas are not contaminated on a regular basis during daily production efforts. These drains are made from the right chemical and bacteria-resistant products to ensure longevity and safe factory conditions at all times. Food-safe drains are not just reserved for food production locations; they can be used in other areas of your property as well.

What are some factors to keep in mind when selecting food-safe drains?

There are various factors that you need to keep in mind when you select food-safe drains for your manufacturing location. These features will help you protect your business from shutdowns and other issues, and they can also ensure that you are creating safe products that consumers will love.

-

Bacteria-Resistance

The drainage that you install on-site at your food manufacturing location needs to be made to prevent the growth of bacteria. Materials like stainless steel are ideal for meeting this goal. Even the smallest amount of bacteria in your manufacturing location can lead to the contamination of the food and products that you create.

You will need to be able to clean and sanitize your drainage to prevent bacterial buildup each day, but you can also make sure that you choose drainage materials that are not prone to collecting thriving bacteria in nooks and crannies. The style and material of your drains are key in areas where bacteria might be present on a regular basis.

-

Highly Durable

Drains that are used in manufacturing locations are often exposed to acidic water runoff, chemicals, and other challenging substances. You can select from an array of durable materials for your drainage system while also picking drains that are up for the challenge of these kinds of liquid products.

Since sanitizing cannot be avoided in the factory environment, it is always good to shop for drains made from materials that will not corrode or break down when they come into contact with tough liquids. Durability can also be linked with placement size and shape of drains, so you might need to work with a drainage installation expert to ensure that you are picking out the right drainage for your specific situation.

-

Rated for Load Bearing

Most food production locations will experience a lot of foot traffic as well as heavy vehicles. There are many different kinds of load ratings that are utilized when creating drainage materials. Each area of your plant might need different maximum load-bearing drainage, as well.

If you have a lot of wheeled traffic in certain areas of your plant or property, you can count on needing to have drainage installed that will hold up to the weight of machines and vehicles. The gratings that you select for these drains will also need to be rated for the things that will pass over them or go on around them all day long.

-

Can Handle Temperature Extremes

The drainage that you install at your food production locale needs to be able to handle tough temperature extremes as well as chemical exposure every day. You will need to be sure that your drainage solution can be exposed to extreme cold and extreme heat each day without breaking or failing.

There are various materials that can be rated for this kind of use, and a drainage expert will be able to tell you the tolerance points of each kind of drainage component. You might also only need to keep this factor in mind in specific locations where the production work that is being done necessitates this swing in temperatures.

-

Easy to Clean

Both the design and the materials that you use for your drainage solution will need to be easy to clean. Being able to easily uncover and clean or sanitize and clean drainage is key to keeping the doors open at a food production business.

There are various tools that can be used to clean each type of drain, but the drain itself needs to be easy to access due to its design and easy to care for due to its materials. Stainless steel is just one example of this kind of drainage product.

-

Certified For Your Kind of Business

Companies that make drainage products will often certify the products that they make for specific functions and locations. You should gravitate toward these kinds of suppliers so that you know that you are getting the right kind of drainage solutions for the job in question. Working with someone who comes in with a cheap quote but who cannot promise the quality or certification of their products is a bad idea.

Certifications should be readily provided by the company that you are working with. These certifications provide proof that the products that a company sells are as effective as they claim. In some industries, certifications for drainage are a legal requirement for food production locations to follow as well.

-

Durability

The drains that you install need to hold up to years of use. If you are not sure what the stated lifetime of each kind of drainage product is, you should be able to get this information from your supplier. Certain materials will enjoy more longevity than others, and these might be the right products to choose for your specific needs.

-

Max Water Flow

It is essential that you know what the maximum water flow will be in any given location on your property. This helps to guide the determination of which kind of grates and what size of drains to install in different areas of your food production location.

Drains can be made in all kinds of shapes and sizes, which allows you to contend even with high volumes of water quite readily. No matter what the normal amount of water that needs to be cleaned up by your drainage solutions is, you need to make sure that your drains are actually rated for the maximum possible drainage needs of each part of your property.

What Kinds of Drains Are Food-Safe?

At the end of the day, any drainage that you install in your food production location should be food-safe. You will need to ensure that you are using the right kinds of drains in each location of your business and that all of the drains that you have placed are the right shape, size, and material for your needs.

-

Slot Drains

These drains have a very low profile and unambiguous opening that allows liquids to flow into a much larger trench drain. These are an ideal drain type for areas where there is a lot of foot traffic as well as places where slips and falls might be common. Slot drains can still remove a lot of liquid waste from surfaces despite their slim and low-profile entrances.

Slot drains are also easy to clean and sanitize and can be placed nearly anywhere and in any kind of flooring.

-

Trench Drains

Classic trench drains often comprise most of the drainage that you will install at your production facility. These drains come in all shapes and sizes and can be customized to your specific needs. They also can be covered by many different kinds of gratings. You can select gratings that are made from the same material as the trench drain itself, and you can opt for covers that are ADA-approved and rate high volumes of water to flow through them. Learn more about Trench Drains for Food Processing Plants here.

-

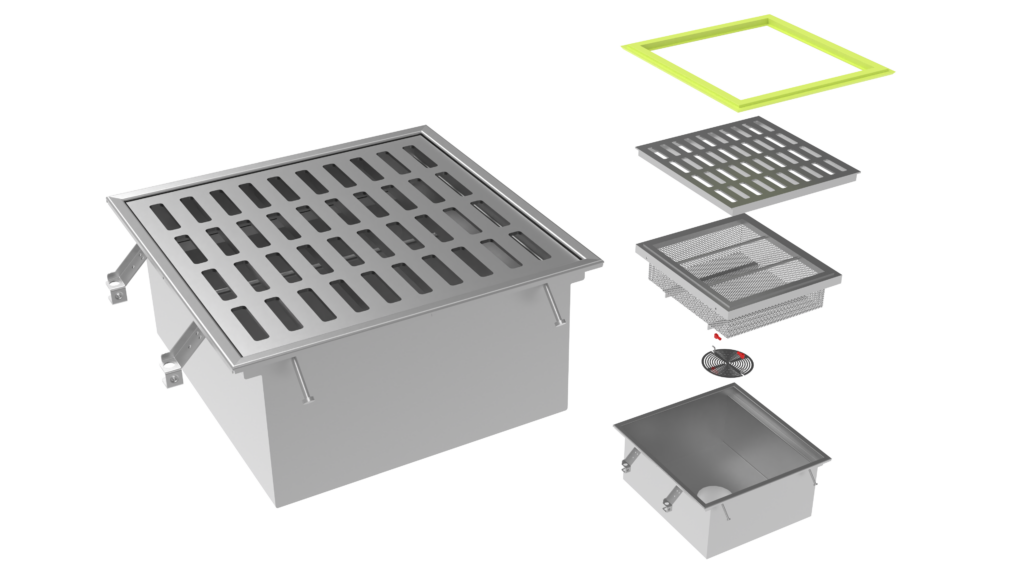

Point Drains

Point drains are made to collect liquid wastes in the center of an area. These drains require a gentle slope that funnels water down into them for removal. While not an ideal solution in areas like hallways or roads, these drains can be perfect in large, square areas where water runoff can be easily collected at the end of a gentle slope.

Point drains are very common in food manufacturing, and you might have numerous locations at your plant that can benefit from installing this kind of drain.

-

Catch and Drain Basins

Catch and drain basins are ideal in locations that contend with large volumes of water runoff from time to time. These basins will continue to collect the water runoff that needs to be removed, even if the drains are almost overwhelmed by it. These collection points will then slowly release the water through the rest of your drainage system.

Catch and drain basins are installed more for emergency use than anything else, although there are some kinds of food production processes that can generate large quantities of water all at once during regular processing efforts. Breweries are a prime example of a location where a catch or drain basin is almost always a must near production areas.

-

Gratings and Drain Covers

For drains that require gratings, you will need to be sure that you are selecting drain covers that will hold up to daily challenges and things like chemical exposure. You will also need to ensure that they will not trip people or cause slips and falls. There are many ways to ensure that your drainage covers actually allow in volumes of water without causing risks to those who pass over the drains all day long.

ADA-compliant drainage solutions still allow a lot of liquid runoff to be captured by drainage solutions without having openings that are large enough to catch feet or heels as people move around your business location.

What Kind of Maintenance Will Food-Safe Drains Require?

In most cases, daily cleaning is required by law at food production facilities. You will likely also be required to use specific grades of sanitizer to ensure that the food that you are producing is safe to eat. You will need to invest in the paddles and brushes that are ideal for the shape of your drainage. You will then just need to ensure that workers are following proper sanitation procedures with the use of these tools each day.

If gratings need to be removed on a regular basis, you might want to opt to pick gratings that will not need to be unscrewed to be removed. You could also elect for slot drains if you need to be able to clean the drains regularly and are worried about people slipping or falling in open trenches due to grates being removed.

Most drainage systems can also be set up to be “flushed” with water during cleanup processes, which can save a lot of time and effort on the part of your staff. A drainage expert should be able to help you determine which of the many drainage types will offer you access to the easiest cleaning methods to save money and time.

Producing Safe Food Products Depends on Installing Safe Drainage

At the end of the day, the quality and safety of the products that you make depend on being able to maintain a safe working environment. Having the right drains installed throughout your factory can help you to ensure compliance with regulations and laws as well as a safe and healthy work environment for your staff.

There are many kinds of drains that can be installed at your factory location, and you will have the ability to customize your drainage solutions to meet your specific business goals. Make sure to work with a team of experts to get access to the drainage solutions that you need at a price that you can afford.