Like every business in the food production industry, dairy farms and plants need to abide by strict safety rules and regulations. Being sure that cleaning and sanitizing are easy each day and ensuring that there is no standing water or moisture in a dairy or at a plant is key. Having the right drainage in place to meet this need is critical if a dairy wants to stay open for business.

There are federal and local government requirements for dairies that must be followed in order for their products to be considered safe. Often, being compliant with these regulations requires that specific kinds of drainage be installed in each area of the plant or farm. Knowing more about what is necessary for this aspect of dairy care and design is key.

Why Do Dairy Plants Need the Right Drainage?

Dairy plants deal with a lot of liquids each day, and there are many cleaning processes that must be completed each day as well. This means that drainage is key to ensure that spills, sanitization fluids, and water are all carried away from the working areas of the plant or farm on a regular basis. Standing water can lead to bacterial overgrowth, which can contaminate the products that are produced in these areas.

Drain systems remove and divert all fluid wastes from the dairy floor. This means cleaning chemicals, dirty water, or even milk and byproducts of it can be easily kept out of the work environment. This makes it simple to keep up with contamination and to prevent issues that might lead to slips and falls, disease risk, and problems with quality control.

Many of the most common industrial accidents are associated with slipping and falling on wet surfaces or catching feet on protruding items on the floor and falling down. Avoiding these kinds of costly mistakes is essential, and the right drainage system in your dairy farm or plant can be of big assistance in these goals.

What Are the Key Features of Dairy-Specific Drainage?

There are various considerations that need to be kept in mind when selecting drainage for a dairy plant or farm. These considerations are not unique to a single location or plant. All dairy locations will need to make sure that the following features are part of the design of every part of the drainage system on-site.

-

Temperature-Resistance

All drainage that is located in any space where pasteurization is taking place will need to be temperature-resistant. Stainless steel is a great choice in areas like this, and it is the most commonly used drainage material in food production locations due to its high durability when exposed to chemicals, heat, and cold.

Pasteurization requires that very cold raw milk is slowly heated to 161 degrees Fahrenheit to kill bacteria, which means that all of the drainage in the areas where this work is done needs to be able to withstand both heat and cold. Floor drain systems will have to tackle tough temperature extremes in order to hold up to daily use in these parts of the plant.

-

Bacteria-Resistant

The drainage that is placed in areas where work is being done with milk products needs to be resistant to growing bacteria. This is another area where stainless steel products really shine. Food products and ingredients can lead to bacteria overgrowth that is hard to check, but having the right drainage products installed in these areas can prevent problems with contamination and illness. Learn more about Food-Safe Drains here.

Milk can carry a host of bacteria like Salmonella, E. coli, campylobacter, and other bacterial strains. This is why the dairy drainage system needs to be so impervious to contamination. If these bacterial strains are present and proliferating anywhere on the property, they can be carried by workers into areas where raw milk and milk products are being made. Even a few bacteria can lead to the contamination of an entire batch of milk, which must be avoided at all costs.

-

Easy to Clean

Your daily drainage needs to be easy to care for and to keep clean. The right style of drainage needs to be installed in the dairy to make sure that every nook and cranny can readily be cleaned and disinfected each day. Slot drains and trench drains with the right kinds of gratings are key when it comes to creating and maintaining a sanitary work space.

In addition, having the right design in place when it comes to drainage in your dairy can save time and effort on the part of your staff. Being able to clean up spills and care for drains quickly and efficiently can help with your bottom line and can ensure that there are no slowdowns during your business days.

-

Load-Bearing

The drains that you install in your dairy will need to hold up to the weight of lots of people standing on them or passing over them and might also have to withstand the weight of vehicles and machines. The drainage that is placed in your dairy will need to be rated for heavy-duty weight-bearing in most cases.

Load-bearing guidelines might also be dictated by state or federal guidelines. Most of these guidelines are specific to the kinds of areas where the drains are being installed. This means that the requirements for a loading bay will probably be different than the requirements for an area where there will only be foot traffic.

Customized drains are key when it comes to weight-bearing considerations, and it is likely that you will have different drainage needs in various areas of your facility to keep in mind as you install your drainage.

-

Corrosion-Resistance

When dealing with acidic substances like chemicals or even food products, it can be necessary to ensure that your installed drainage is corrosion-resistant. Sanitizing areas where food is prepared and made can require harsh chemicals to be used on a daily basis. Whatever drainage components are exposed to this drainage need to be able to withstand the nature of this kind of liquid run-off.

Stainless steel is one of the best kinds of materials for conditions such as these, and many food manufacturing locations, as well as places like breweries, also have to install stainless steel drainage to ensure that acidic or caustic substances don’t break down pipes, drains, and grates. Learn more about why stainless steel trench drain systems are good for food production here.

-

Correct Size

The size of the drains that are installed in different areas of a facility is dictated by the proposed maximum volume of liquid matter that will need to be drained off surfaces in a day. This is easier to calculate than in the case of outdoor drainage, as there is no rainfall to keep in mind. You will just need to be sure of the maximum amount of liquid that might need to be handled by your drains to be sure about the size of the trenches or slot drains that you install.

There are many sizes and shapes of drains that you can select for your dairy drainage system, and picking the right combination of these features matters. You will be much less likely to struggle with drainage issues during daily operations if you have calculated the maximum possible water flow in any given area of the dairy at any given time.

-

Regulation and Code

All dairies will need to abide by regulations and codes set forth by the local and federal government. These codes and rules will help to determine the size and shape, as well as the placement of much of your drainage in your dairy location. Having these guidelines on hand can make it simple to select the perfect drainage for your needs without any guesswork.

If you have hired a skilled installation team to work on your dairy drainage installation job, they will know which rules and regulations that you need to follow when placing drains and choosing their size and features. This can simplify much of the drainage design process, and it can make your installation job pretty foolproof.

What Kinds of Drains Are Common in Dairies?

There are many kinds of drains that might be placed in a dairy location. The different areas of the dairy will likely need different drainage as well. You might have many kinds of drains and drainage components installed in your dairy once your drainage system is complete.

-

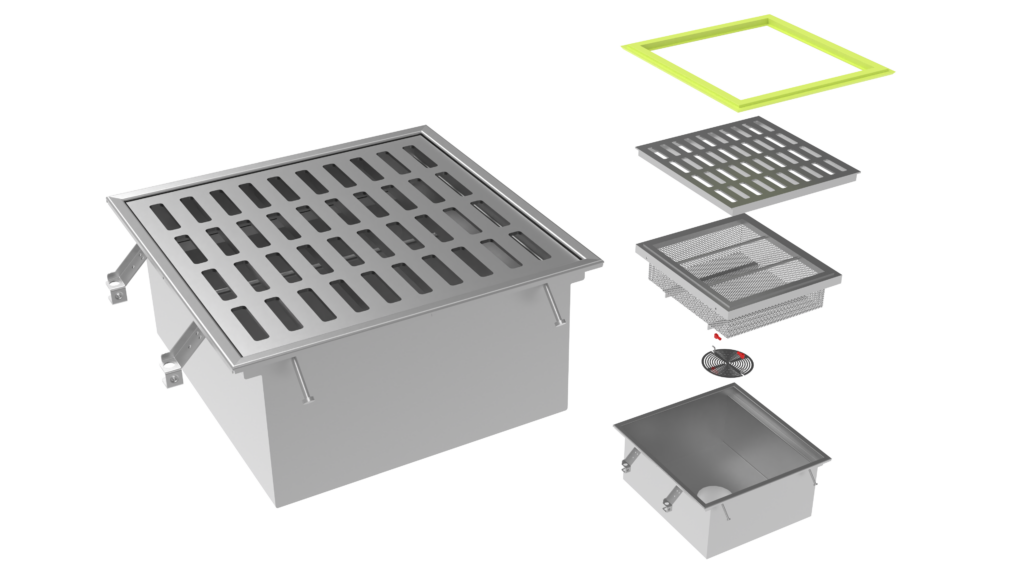

Point Drains

These are very common in dairy locations because point drains are placed at a focal low point to collect water runoff that is running from other areas of the floor with ease. This might not be possible in all of the spaces in your dairy, but having a few central floor drains that are made to collect runoff via gravity can be really ideal in a dairy.

These drains are also unlikely to cause tripping accidents or hazards for foot traffic, which is another essential benefit of their use.

-

Trench Drains

Trench drains of various kinds are usually the most common kind of drain in a food processing location. These drains come in all shapes and sizes and can be fitted with custom grates to prevent things like slips and falls, debris from getting into the drains, and hazards for passing wheeled traffic.

Drainage grates for trench drains can be made to screw into place, can be crafted with ADA-approved slots and holes, and can also be made to allow as little or as much fluid matter to run into your drains as you wish. The trench drain and its accessories can also be made of any material, which can be essential when it comes to maintaining healthy, safe workspaces.

-

Slot Drains

These low-profile drains are ideal for places where there is a lot of wheeled traffic or where lots of people will be passing over your drains on foot. The small opening of a slot drain gives way to a much larger trench drain underneath the surface of the floor. This kind of drain admits far less to debris, and it is also barely visible even when you are standing right by the drain opening.

Slot drains might seem like they will allow less water to enter the trench drain below the surface of the floor, but that is not actually the case. Slot drains can be made to allow as much water runoff as you wish and come in all kinds of shapes and sizes.

-

Catch Basins and Drain Basins

Catch and drain basins are often standard in dairy locations. These basins are made to capture and hold water runoff that is generated suddenly and at a fast rate. This is more common in locations where precipitation might lead to flooding, but in a dairy, they are placed in areas where an equipment failure or spill might make them necessary. Since there is a high volume of liquid runoff generated on the floor of a dairy plant each day, it makes sense to be sure that it will be collected below the floor surface and allowed to drain properly.

Even in the event of a sudden flood of moisture, catch or drain basins will be able to capture the fluid wastes that are being generated and remove them properly. This also helps to prevent bacterial overgrowth and shutdowns due to flooding.

Dairy Drainage Requires Careful Thought and Planning

As with all food production locations, dairies need to be able to remove excess water runoff from production floors and other areas where food products are being created. Without the right drainage solutions in place at your dairy, you might not be able to stay open for business due to the risk of contamination and other health risks to employees and consumers.

Dairy drainage can be made from a variety of materials and can be produced in a variety of different designs. Always be sure to work with a skilled installation and design team before you start installing the drainage at your dairy or plant. Installing compliant drainage that is rated correctly for the needs of your business is key.