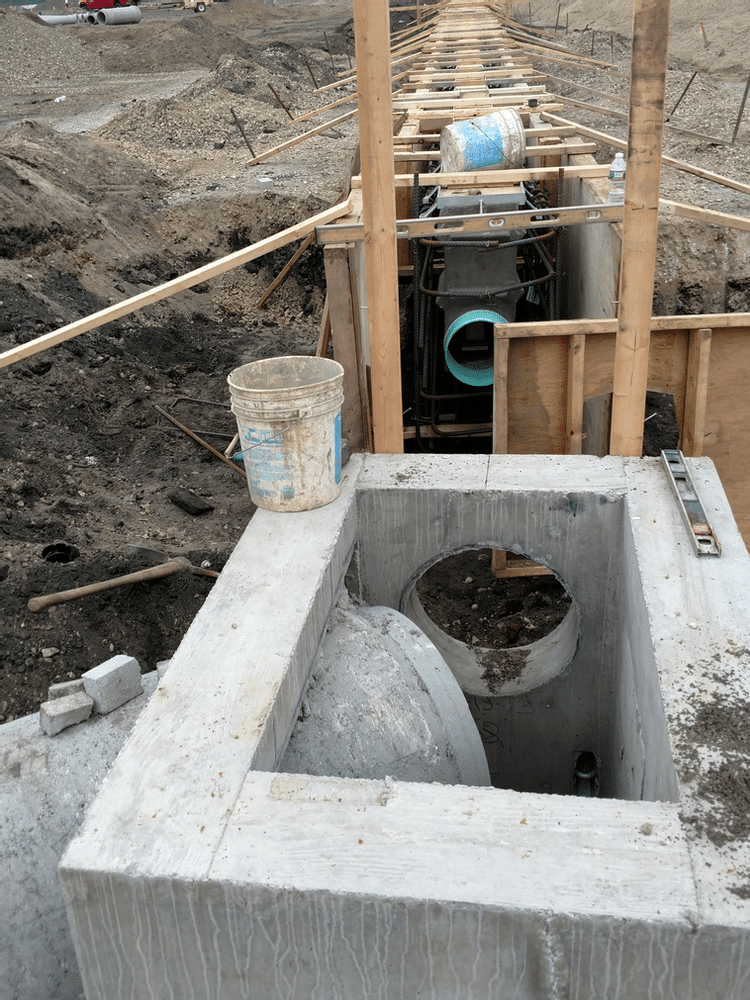

Making the connection between a trench drain system and a concrete manhole can be a time consuming task if it was not planned properly. Two types of connection are common. The first is to stop the trench drain back from the structure and transition to a pipe. The second is to bring the trench drain into the structure without any restrictions (note we call this connection type a “snout”). This second option when properly executed allows for the trench drain to reach maximum flow capacity without restrictions.

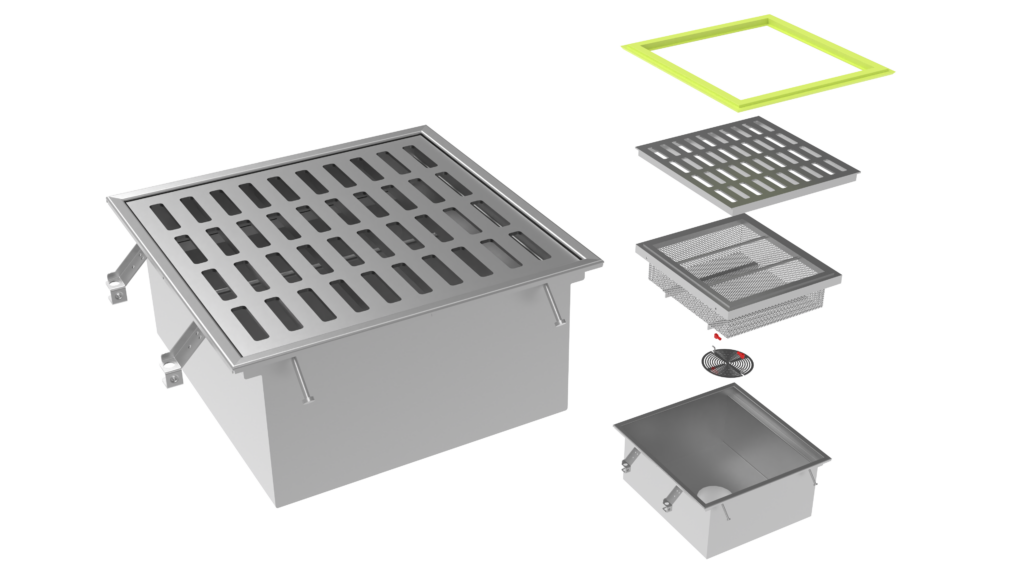

Before we talk about the hole in the structure we need to talk about the trench drain depth. The precast concrete manhole typically will have a lid that ranges from 8″ to 12″ thick. The trench drain system will need it’s outlet connection to get under this lid. If you want to use an 8″ pipe and you have an 8″ lid then the trench needs to be a minimum of 16″ deep (and preferably a couple inches more) to come out the end. If you do not have this depth the a pipe will require an elbow. This is a place where debris can block the system and is typically avoided. The other option is the snout. A snout will have a drop down in the trench that turns the full flow below the concrete lid. Make sure you tell the trench drain manufacturer what the lid thickness is so that they can manufacture this piece at the proper height.

Ideally, the structure should be ordered with a hole to accept the trench drain or it’s outlet pipe. In order to do this the width and depth of the trench drain must be determined early on in the project. When planning this hole size make sure it is a good bit wider than the pipe or trench entering the structure. The structures are rarely perfectly aligned so the extra space will help to make sure the alignment of the trench can be maintained without modifications to the precast structure. Typically for a snout connection we like about 6-8″ wider and 6-8″ deeper than the trench drain itself. If using a pipe connection try to get about 2 sizes bigger than the actual pipe (so if using a 4″ pipe order an 8″ hole).

If a pipe was used it is easiest to get some non-shrink grout to seal around the pipe and close the hole. For a snout connection it is typical to place a form board on the inside of the structure and place concrete in the void during the concrete installation around the trench drain.