One of the most unique locations that Dura Trench makes trench drains for is breweries and distilleries. These locations have their own requirements for function and for drainage, and expert attention is needed to get the right drain solutions in place in any brewery.

Part of the challenge for these locations, is often that the buildings they are located in are retrofit locations that were not at first intended for brewery use. This can create challenges to do with the slope of the floor and space might be limited for the drain to be installed. Installing the correct drain is a major factor in the longevity of the usefulness of the brewery location, and it is important for the brewery to have proper drainage so that it can pass inspections each year.

If you want to learn more about breweries and their trench drain needs, read on!

All There is to Know About Trench Drains for Breweries

Water usage at a brewery location can be quite high. Often the water usage is double or triple the volume of the beer that is being made at the location. All of this liquid needs to be drained off properly during daily work processes, or there will be sanitation issues at the brewery location.

There are various locations that drains will need to be installed in the average brewery, and they will all need to work perfectly for the brewing process to be conducted correctly and with proper sanitation in place.

- Between fermenters

- Inside the walk-in cooler

- Bottling or packaging areas

- Storage facilities

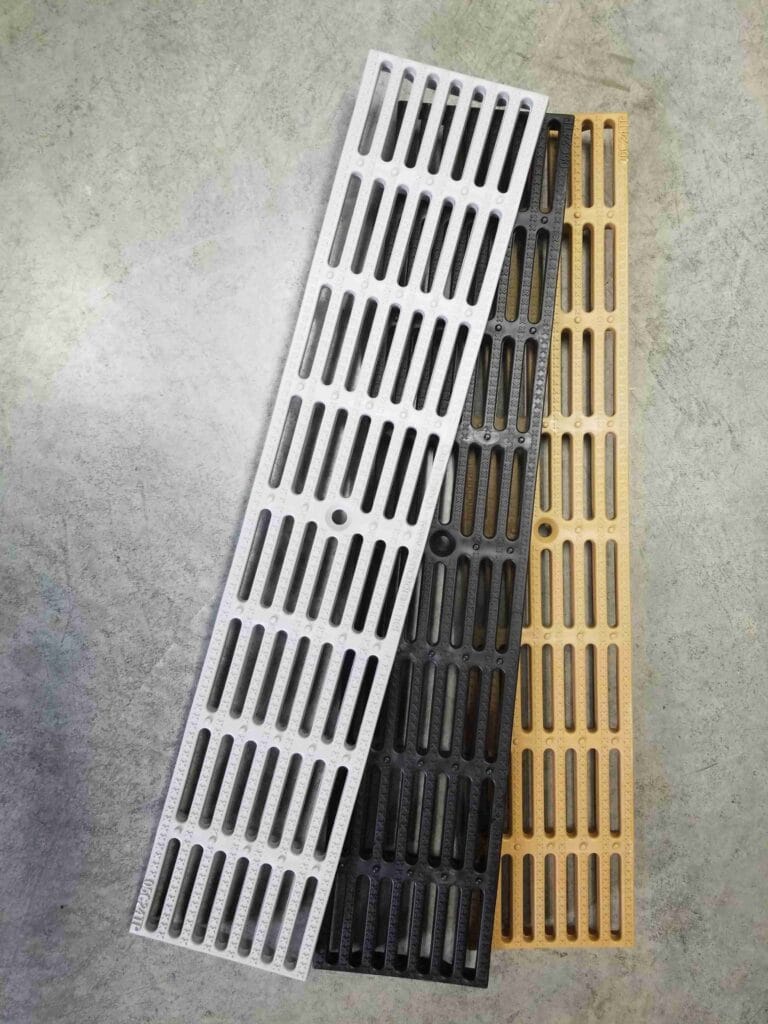

Linear trench drain systems work in all of these locations, and are the preferred solution to this requirement for almost all brewery designs. Slot drains, catch basins, and trench drains are the most common solutions to the drainage needs of a brewery.

What Kinds of Material Should Your Brewery Drains be Made Of?

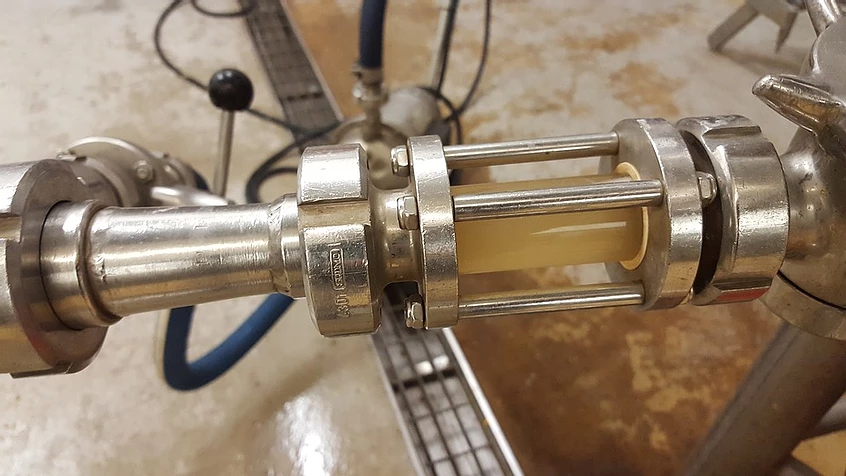

Because brewery wastewater has a high pH level, you will need to make sure that you install the right kind of trench drains to handle this. You will need to consider solutions that are made for chemical runoff rather than simple water. Stainless steel is often the best choice for this demand because it can stand up to the hydrogen sulfide gas that is in the wastewater.

In addition, you will need to select slot covers and other accessories that will hold up to the demands of daily use in the brewery setting. You will likely need to install stainless steel items throughout your drainage system.

What About Solids in the Wastewater?

This is often one of the biggest challenges in the brewery wastewater management plan. Solids can form sludge at the bottom of the drain and this sludge can break down the materials of the drain, or slowly clog the trench to the point where it no longer works.

To solve the collection of solids, you will want to install a slot drain. These drains have covers over the opening that collect solids that could otherwise clog the drain or damage the entire drainage system. This will also prevent large bills that are related to the cleaning of clogged drains.

If you are going to be processing a large amount of solids each day, you can double up your protection by adding a catch basin. This handy add-on will catch any of the remaining solids that slip through the slot drains, preventing any risk of clogs, damage, or slowdowns in the trench drainage system.

Making Sure to be Environmentally Friendly

This is one of the biggest reasons that proper drainage matters. Incorrect drainage solutions in your brewery will not only affect your work hours and the speed and ease with which you can produce your product, but they can also cause harmful damage to the overall environment around your brewery.

Solids and the chemicals that are byproducts of brewing can lead to harmful effects on the local ecosystem. Runoff can be toxic to animals and you might accidentally be dumping wastewater into local waterways. This is an important part of the reason for having a good quality drainage solution in place at your brewery.

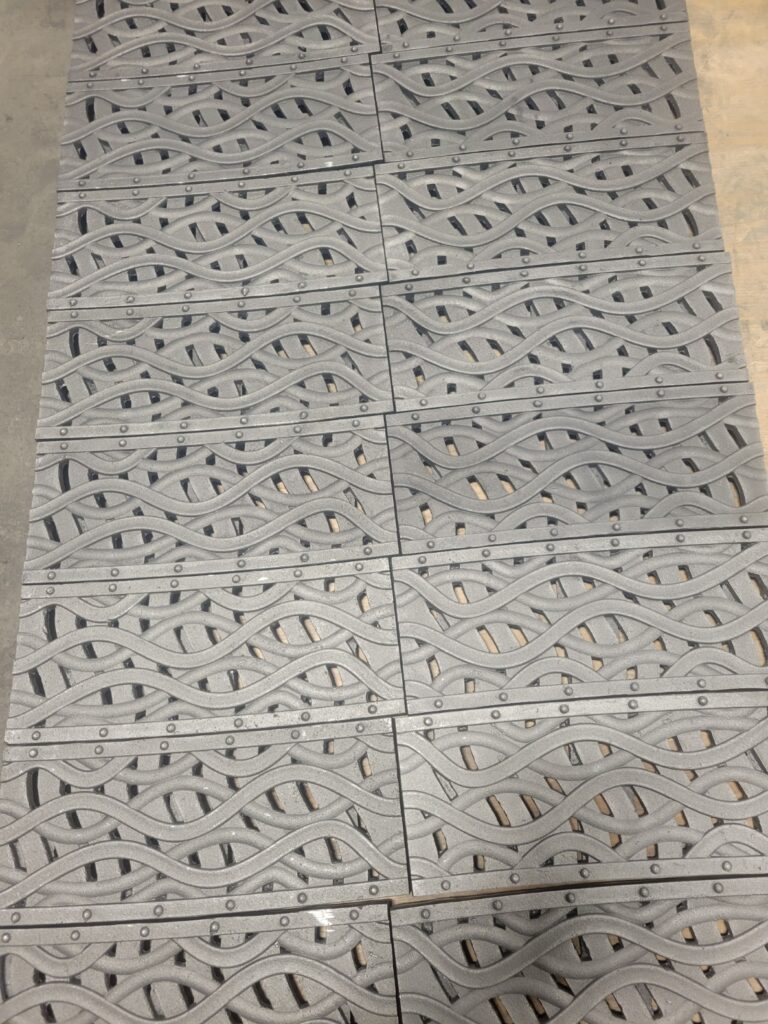

Preventing Slips and Falls with Adequate Brewery Drainage

Good drainage is also necessary to prevent slips and falls in your brewery. Sludgy water and solids can actually greatly impact the safety of flooring inside the brewery and messy floors can lead to injuries to yourself or your employees.

Having adequate drains in place will prevent issues related to worker safety while also helping the environment and keeping messy and toxin-filled water from ending up in the local wastewater plant. A clean brewery is a happy brewery.

Proper Brewery Drainage Installation is Key

If you have realized that you need to upgrade your drainage solutions in your brewery, you might be concerned about selecting the right business to install your new drains. You will want to be sure that the company that installs your drains knows about the needs and demands of brewery spaces before you agree to have them install your drains.

Prevent Bacteria Growth

Unlike other locations like pool surrounds, or yard drains, slot drains in breweries can be the perfect location for bacteria to take root and start to grow. An experienced installer will know to make certain that there are no crevices that will collect solids, or standing water and start to grow bacteria.

Another factor that is important when you are trying to combat bacterial overgrowth, is making sure that there is enough of a grade or slope to the floors that wastewater will end up in the drains. An experienced installer will look at the entirety of the brewery workspaces to make sure that the flooring has enough of a grade to be able to drain into the slot or trench drain that has been installed.

Identifying Problems with the Flooring

Another important factor that some drain installers will not be aware of, is the need to evaluate the floors that the drains are being installed in. The floors of any industrial space can take a beating each day, and segmented or cracked concrete will cause impediments to proper drainage. You can install the perfect drain, but if the floor around it is not smooth and properly graded, water and other materials will not run into that drain correctly.

While correcting issues with the flooring itself is not really the job of the drain installers, a good trench drain company will be able to advise about these issues before starting the installation of the drains.

Size Matters For Your Brewery Drainage

No matter what kind of drain is being installed in a brewery location, the right size drain will need to be put in to handle the needs of the processes in that unique space. Drains near brewery equipment will likely need to handle a much higher volume of wastes than those that are located in areas where liquids are much less likely to spill or be drained.

4” drains can handle 350 gallons per minute, and drains that are even larger might be needed to handle the requirements of certain spaces. To figure out the proper sizing of the drains that are installed, the installing company will need to know how much water is being moved through the area on any given day, and the volume of material that is processed each day and each week.

Trench Size is Important

Just like drain sizing, the depth and width of the trench itself matters too. The higher the volume of water and other liquid waste that needs to be handled each day, the larger the drain that needs to be installed.

One of the tricks to planning correct drainage in a brewery, is that there are often high volumes of fluid moving through the drains all at once. This is not a consistent demand of the trench, but one that it needs to be able to meet during certain parts of the brewing process.

Planning drains or trenches based on the baseline of activity rather than these times where large amounts of fluids are being removed is not wise. You will need to make a plan for the drains and trenches based on the highest volume demands that the brewery will experience, rather than the minimums of daily operations.

Ideal Trench Types for Brewery Settings

In brewery settings, you cannot use flat-bottom drain styles as they will collect standing water and solids. This can lead to unsanitary conditions and overgrowth of bacteria. In addition, the pH in the standing water in these types of drains will often eat away at the drain and cause damage to the entire drainage system.

In many breweries, deep trenches are the standard to help handle the volume of fluids involved and to ensure that the necessary slope can be created to allow water to exit the drainage system properly. This depth may affect the kind of trenches that need to be installed in your brewery, and an expert installer can advise you about the right trench for the needs of the building’s flooring, existing drains, and other concerns.

Outlets Need to Have Catch Basins

Any location where solids might slip through or become mixed into the wastewater needs to be addressed with catch basins. This might be corners where two drains connect, or it could be at the outlets where drains of different sizes merge. This is good housekeeping and it prevents messy, sludgy runoff, as well as drain clogging.

This is also a great solution to make clean-up processes much easier. There is nothing cheap or easy about cleaning out the entire drainage system as a whole but cleaning out a catch basin is really no trouble at all.

Make Sure that Sumps Are Not Needed for Your Brewery Drainage System

Sumps may sometimes be needed to handle large volumes of sludgy runoff full of solids from contaminating the environment or becoming a hazard to the local wastewater plant. These sumps can be planned into your drainage solution, and there are a variety of models of sumps that can be used to deal with pH issues and sugars and other contaminants in your brewery’s run-off water.

While the initial cost of the sump might feel like it’s an added investment that you don’t want to make, being able to attend to your wastes properly is a major factor in passing inspections and being a good neighbor to the properties and the wildlife around your brewery. Sumps are also easy to care for and manage, making them a great solution for attending to environmental concerns.

Make Sure to Get Professional Help With Your Brewery Drainage Design

As mentioned earlier, many breweries are not located inside of buildings that were intended for brewing. There will always be challenges in these spaces that are related to water quality, collecting solids, and handling the large volumes of liquid wastes generated in the beer-making process.

Crossing your fingers and hoping you have made a good plan will not create a viable drainage solution for your brewery. You will need to get the help of an expert who knows how to troubleshoot drainage difficulties and come up with the right solutions for your needs.

In addition, there are many kinds of trench drain and slot drain products on the market, but not all of them will be a good fit for your needs. Being able to remove the guesswork from the installation process is a major benefit to securing the help of professional service to plan your drainage system in your brewery.

Upgrading Your Brewery’s Drainage is a Great Investment

If you are ready to upgrade your drains to a better and more environmentally friendly design, we at Dura Trench can help! There is no drainage need too big or too small for our experts, and we are more than happy to visit your location and create a quote for your needs.

Dura Trench products are perfect for the demands of brewery settings, and the right drainage solution is easy to create with our help and expertise.