Fabricated metal trench drain grates are combinations of surface plates and load bars. The surface plates are cut or punched to the desired pattern and size. Load bars are cut and welded to the back side of the plate to add strength. Finally the fabricated metal trench drain grates are finished with galvanizing, painting, powder coating, electro polishing, sand blasting, brushing, or other finishes.

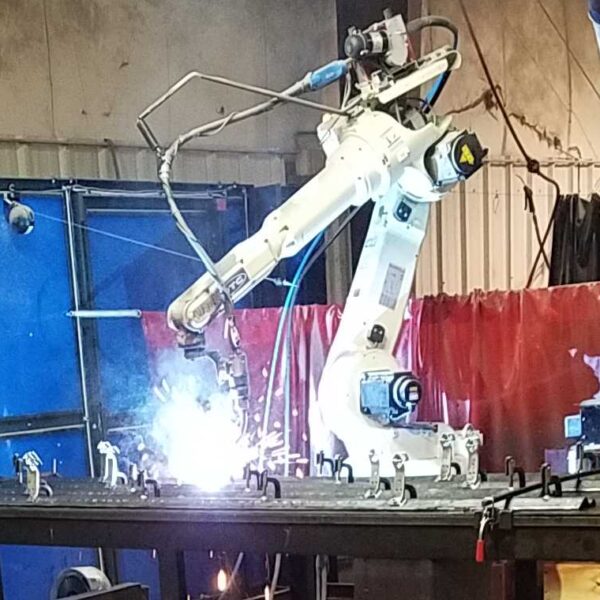

The Dura Trench difference is the highly automated process used to manufacture our fabricated trench drain grates. We use a variety of in house CNC equipment to process the bars and plates, then use robotic welding to ensure high quality connections, and finally use automated sandblast and surface finishing equipment. This ensures high quality and consistent products at high production rates.

A fabricated metal trench drain grate can reach any load class. We do this by first working with our engineering team to accurately model and test the trench drain grate. The trench drain grate is load tested using finite element analysis to ensure it will meet the required load rating. Plate thickness, hole spacing, bar size, and bar quantity can all be varied until the design requirements are met. The individual trench drain grate components are then output to our CNC equipment for cutting and programming of robotics and finishing. The process ensures high quality grates meeting the customer’s specifications.